Pharmaceutical Manufacturers Solve Contamination Problem with CleanSeal® Door Systems

Posted Tuesday, June 19th, 2018

Most pharmaceutical manufacturing facilities have a steady flow of traffic in and out of their buildings. Employees and vendors are constantly handling materials, packaging product, and moving that product in and out of various rooms. With all of this activity, contamination is a serious concern.

Room separation is also an important consideration for pharmaceutical manufacturers. Each area must be isolated to avoid contamination of products between rooms. Often, there is a hallway connecting rooms, and this can be another source of contamination.

What’s more, FDA guidelines mandate specific requirements for good manufacturing practices. (cGMP) Included in these requirements are optimal environments for both employees and products. Specifically, the amount of airborne particles allowed must be limited in order to control contamination within an area.

How can pharmaceutical companies meet all the demands of the FDA and implement a solution that is functional in such a busy environment? At Cressy Door and Fireplace, we have a solution.

CleanSeal® door systems from ASI are designed specifically for high traffic environments with FDA compliant mandates. Not only that, they are heavy-duty and easy-to-clean. Our customers like CleanSeal® door systems because the doors open and close quickly assuring the tightly controlled environment required.

CleanSeal® Door Options

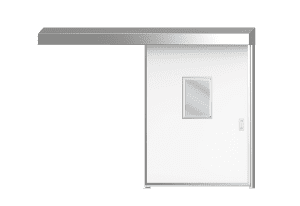

CleanSeal® Sliding Doors

CleanSeal® Sliding Doors

CleanSeal®’s sliding cleanroom door systems are designed, engineered and precision manufactured. With over 20 years of experience, they have partnered with leading pharmaceutical companies, biotech companies and architects from across the globe. CleanSeal® provides complete door systems with styles that meet cGMP, EMEA, FDA, ISO and Cleanroom requirements to Class 1 (ISO 3). .

View complete line of CleanSeal® Sliding Doors

CleanSeal® Swinging Doors

CleanSeal® Swinging Doors

Finished pharmaceuticals, biopharmaceuticals and most medical devices are produced in a cleanroom environment. CleanSeal® has responded to the needs of these expanding life science markets by offering complete swing door systems. Each system includes panel choice, frame design, hardware and interlocking designs. Available styles include options designed to meet cGMP, ISO 3–Class 1 Cleanroom requirements.

View complete line of CleanSeal® Swinging Doors

CleanSeal® Roll Up Doors

CleanSeal® Roll Up Doors

Compliment your swinging and sliding doors with CleanSeal®’s high performance fabric roll-up doors. Perfect for applications where speed and reliability are critical factors in creating an efficient operation. With plenty of styles and options to choose from, CleanSeal® fabric roll up doors are ideal for pharmaceutical, cleanroom and GMP applications; including packaging, material transfer, air locks, equipment wash rooms and staging areas.

View complete line of CleanSeal® Roll Up Doors

CleanSeal® Fire Doors

CleanSeal® Fire Doors

CleanSeal®’s fire door systems are designed specifically for clean environments. They offer great looks and amazing clean-ability, plus, the protection you need in an emergency. These doors meet GMP and U.L. compliance.

View complete line of CleanSeal® Fire Doors

CleanSeal® Specialty Doors

CleanSeal® Specialty Doors

CleanSeal® specialty doors provide unique solutions to complex door application challenges. From space saving telescoping doors, to high speed exterior roll-ups that provide security and access control, CleanSeal® has you covered.

View complete line of CleanSeal® Specialty Doors

Not sure which CleanSeal® Door Options are right for your situation? Give the team at Cressy Door and Fireplace a call. One of our CleanSeal® door sales reps will be glad to assist you. You may be surprised to learn about CleanSeal®’s extensive capabilities.